Basic coated electrode for welding duplex and surfacing applications of a similar type austenitic steels. Excellent weldability, very high resistance to stress corrosion cracking.

Features and Applications

Applicability in welding duplex steels

Suitability to joint - and surfacing applications of similar-type austenitic steels and cast steels

Electrode coating of basic character

Excellent weldability

Very high resistance to stress corrosion cracking and to corrosion at particularly chlorious and sulphurous media

In the liquid conditions at chemical industry, serviceability at temperatures of values up to 280°C

Re-drying: 250°C - 300°C / min. 2h

Typical Base Material Grades

X2CrNiMoN22-5-3, X2CrNiMoN23-4, X2CrNiMoN22-5-3 with X2CrNiMoNb18-1, X2CrNiMoN22-5-3 with P235GH/ P265GH, S255N, P295GH, S355N, 16Mo3

| Standards |

Current Type |

EN ISO 3581-A - E 22 9 3 N L B 22

|

D.C. (+)

|

AWS A5.4 - E 2209-15

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Si |

Mn |

Mo |

Ni |

Cr |

N |

| 0.03 |

0.4 |

1.3 |

2.6

|

9.0 |

22.0 |

0.14 |

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/+20ºC)

|

Impact Strength

(ISO-V/-60ºC)

|

Elongation

(Lo=5do)(%) |

min. 520

|

690 - 850

|

min. 80 J |

min. 40 J |

min. 30

|

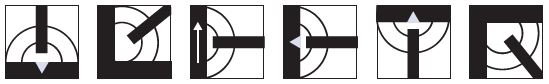

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

Carton

Weight (Kg) |

|

2.50 x 250

3.20 x 350

4.00 x 350

|

60 - 80

80 - 110

110 - 140

|

3

4.5

4.5

|

12

18

18

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.