Rutile coated stainless steel electrode for high resistant steels, alloyed / unalloyed steels, heat resistance, Cr-stainless steels including 14% Mn and hard to weld steels. Suitable for dissimilar welding with excellent resistance to thermal shock.

Features and Applications

High resistant steels, alloyed / unalloyed steels, heat-resistant steels, Cr-stainless steels, steels including 14%Mn , hard-to-weld steels

Joint welding and filler welding of difference metal with each other

Electrode coating of rutile character

Austenitic weld metal with resistance to thermal shocks

Maintenance of toughness at temperatures down to -100°C

Requirement of re-drying for min. 2 hours at the temperatures between 120°C and 200°C

Typical Base Material Grades

DIN:X 7 Cr 13, X 7 Cr Al 13, X 10 Cr 13, X 8 Cr 17, X 20 Cr 13, X 10 Cr Al 7, X 10 Cr A 13, X 15 Cr 13, X 22 CrNi 17, X 5 CrNi 134, X 8 CrTi 17, G-X 20 Cr 14, G-X 8 CrNi 13, G-X 30 CrSi 6

AISI: 405, 410, 420, 430, 430 Ti, 431, 440, 502

| Standards |

Current Type |

EN ISO 3581-A - E 18 8 Mn R 32

|

D.C. (+) / A.C.

|

AWS A5.4 - E 307-16

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Si |

Mn |

Ni |

Cr |

| 0.11 |

1.0 |

4.5 |

8.5

|

19.0 |

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/+20ºC)

|

Elongation

(Lo=5do)(%) |

min. 390

|

600 - 770

|

min. 47 J |

min. 30

|

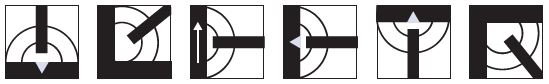

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

Carton

Weight (Kg) |

|

2.50 x 250

3.20 x 350

4.00 x 350

|

60 - 80

80 - 110

110 - 140

|

3

4.5

4.5

|

12

18

18

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.