Used for welding 347 and 321 stainless steels, resistant to acid and corrosion, stabilised by Niobium. Ideal for use on pressure vessels, food and process plants.

Features and Applications

Used for the welding of tanks and pipes in which milk and beer is kept

Also used for the welding of acid, gas, steam and water armatures

Resistant to acid and corrosion, stabilized by Nb. Weld metal can resist to temperatures up to +400°C

Requirement of Re-drying for min. 2 hours at the temperatures between 120°C and 200°C

Typical Base Material Grades

EN: X6CrNiNb 18 10, X6CrNiTi 18 10, G-X5CrNiNb 18 9, X5CrNi 18 10, X12CrNiTi 18 9, G-X10CrNi 18 8, X10CrNiNb 18 10, X2CrNi 19 11

AISI: 347, 321, 304, 304LN

| Standards |

Current Type |

EN ISO 3581-A - E 19 9 Nb R 32

|

D.C. (+) / A.C.

|

AWS A5.4 - E 347-16

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Si |

Mn |

Mo |

Ni |

Cr |

Nb |

| 0.04 |

0.8 |

0.9 |

2.6

|

10.0 |

19.8 |

+ |

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/+20ºC)

|

Elongation

(Lo=5do)(%) |

min. 390

|

570 - 740

|

min. 47 J |

min. 30

|

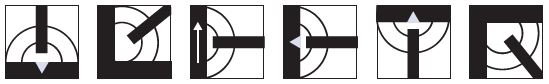

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

Carton

Weight (Kg) |

|

2.50 x 250

3.20 x 350

4.00 x 350

|

50 - 90

80 - 120

110 - 160

|

3

4.5

4.5

|

12

18

18

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.