Basic coated electrode with nominal 0.5% Mo alloy resulting in improved elevated temperature performance over that of CMn steels. Typically used on vessels, pipe work where creep rupture strength and ductility is required.

Features and Applications

Basic-coated stick electrode

Welding of heat-resisting, Mo-alloyed, thin-walled and unalloyed steels used for construction of boilers and pipes

Weld metal is resistant to working temperatures from -50°C to +550°C Re-drying: 300-350°C min. 2h

Vacuumed packed electrodes

Typical Base Material Grades

S355J2G3, E295, E335, P255G1TH, 16Mo3, L320-L415NB, L290MB-L415MB,S255N-S460N, P295GH P355GH, 15NiCuMoNb5S, 20MnMoNi4-5, 17MnMoV6-4, S255NH-S460NH, S255NL- S460NL, GE240-GE300, GS22Mo4

| Standards |

Current Type |

EN ISO 3580-A - E Mo B 42 H5

|

D.C. (+)

|

AWS A5.5 - E7018-A1 H4

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Si |

Mn |

Mo |

| 0.07 |

0.4 |

0.9 |

0.5

|

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/-50ºC)

|

Elongation

(Lo=5do)(%) |

Heat Treatment |

min. 460

|

530 - 670

|

min. 47 J |

min. 22 |

620ºC/1hr

300ºC (air) |

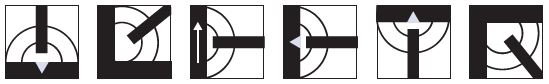

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

Carton

Weight (Kg) |

|

2.50 x 350

3.20 x 350

4.00 x 450

|

80 - 110

100 - 140

130 - 190

|

2

2

3

|

12

12

18

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.