Basic type electrode used for the welding of heat resisting steels containin 5 Cr - ½ Mo at elevated temperatures up to 600°C. Applications include piping and boiler super heaters.

Features and Applications

High-heat-resistant steels

In petrochemical industry and on pressured-hydrogen tanks

Serviceability of weld metal at working temperature up to 600°C

Requirement of re-drying for min. 2 hours at the temperatures between 300°C and 350°C

Vacuumed packed electrodes

Typical Base Material Grades

X12CrMo5, GX12CrMo5

| Standards |

Current Type |

EN ISO 3580-A - E CrMo5 B 42 H5

|

D.C. (+)

|

AWS A5.5 - E8018-B6 (E 502-15) H4

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Si |

Mn |

Mo |

Cr |

| 0.06 |

0.4 |

0.8 |

0.5

|

5.2 |

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/+20ºC)

|

Elongation

(Lo=5do)(%) |

Heat Treatment |

min. 460

|

min 590

|

min. 47 J |

min. 19

|

730-755ºC/1hr

300ºC (air) |

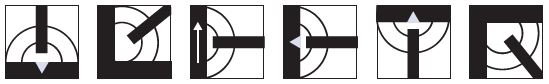

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

Carton

Weight (Kg) |

|

2.50 x 350

3.20 x 350

4.00 x 450

|

65 - 90

110 - 130

140 - 180

|

2

2

3

|

12

12

18

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.