All positional electrode for welding Inconel 625 offering high temperature strength and structural stability. It is widely used for its resistance to general stress corrosion cracking.

Features and Applications

High Molybdenum Nickel-base alloy electrode for creep-resistant steels, heat resisting steels, heat resisting and Cryogenic materials, dissimilar joints and high strength problem steels

Especially designed for Inconel 625 and Incoloy 825

Re-drying conditions. 250°C - 300°C / 2h Typical

Typical Base Material Grades

1.4529 X2 NiCrMoCu 25 20 6, 1.4583 X10 NiCrMoNb 1812, 1.4876 X1O NiCrAITi 32 20

(incoloy800), 1.5662 X8 Ni 9 (ASTM 9Ni), 2.4816 NiCr 15 Fe (inconel 600), 2.4856 NiCr 22 Mo9 Nb (inconel 625), 2.4858 NiCr 21 Mo (inconel 825), 2.4951 NiCr20Ti (ASTM 75), 2.4952 NiCr 20 TLN (ASTM 80A) ASTM 8443, 8444, 8446 (UNS N06625)

| Standards |

Current Type |

EN ISO 314172 - E Ni 6625 (NiCr22Mo9Nb)

|

D.C. (+)

|

AWS A5.11 - E NiCrMo-3

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Mn |

Si |

Mo |

Ni |

Fe |

Cr |

Ti |

Nb |

| 0.04 |

0.4 |

0.7 |

9.0 |

Rest |

5.0 |

21.0 |

+ |

3.5 |

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/+20ºC)

|

Impact Strength

(ISO-V/-196ºC)

|

Elongation

(Lo=5do)(%) |

min. 420

|

min. 760

|

min. 60 J |

min. 35 J |

min. 30

|

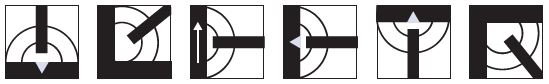

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

Carton

Weight (Kg) |

|

2.50 x 250

3.20 x 300

4.00 x 350

|

60 - 80

70 - 100

90 - 130

|

3

4.5

4.5

|

12

18

18

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.