Manual welding electrode suitable for welding forged and cast aluminium alloys including crack repair, casting defects and building up sections of broken parts. Recommended to preheat at 200°C for welding thick sections.

Features and Applications

Includes also engine blocks, gear cases, engine gear box unit, miscellaneous components in light alloys, storage tanks, containers, vessels, repair works on various kind of aluminium materials

Manual welding electrode recommended for production and maintenance applications including repair of cracks, casting defects and building up sections and fixing broken parts

Suitable for applications using aluminium

Before welding on thick section pre-heating to about 200°C is recommended

Hermetically sealed tin cans

| Standards |

Current Type |

TS 9604 - EL-AlSi 5

|

D.C. (+) / A.C.

|

AWS A5.3 - E 4043

|

|

| Chemical Composition of Weld Metal % (Typical) |

| Si |

Al |

|

|

|

|

|

|

|

| 4.5 - 5.5 |

Rest |

|

|

|

|

|

|

|

| Mechanical Properties |

Yield Strength

(N/mm2) |

Elongation

(Lo=5do)(%) |

Hardness (HB)

|

160 - 190

|

min. 10

|

50

|

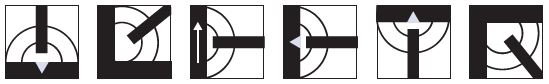

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

|

2.50 x 350

3.20 x 350

4.00 x 350

|

50 - 80

70 - 100

90 - 130

|

2

2

2

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.