GrabPak is a handy and convenient way of supplying customers with just the right amount of electrodes for any small jobs in the home or workplace. Designed to increase sales through the presentation of our popular welding consumables in a rotating stand with full colour coded 0.5kg packaging.

Stainless steel rutile coated low carbon electrode for use in high strength, unalloyed and heat treatable steels, ferritic Cr and austenitic CrNi steels. Ideal for dissimilar metals, buffer layers on mild steel and low alloyed steels prior to build up or overlaying.

Features and Applications

Rutile coated low carbon electrode for use in high strength unalloyed and heat treatable steels, ferritic Cr and austenitic CrNi steels, austenitic Mn steels

Similar type austenitic stainless steels, dissimilar metals, buffer layers on mild and low alloyed steels prior to build up or overlaying with any stainless electrodes, joining of corrosion resistant stainless steel with mild or low alloy steels, clad steels

Good crack resistance with hard to weld steels

The weld metal contains a high ferrite %

Requirement of re-drying for minimum 2 hours at temperatures between 120°C-200°C

Unalloyed tempered steels, tool steels, hard manganese steels and hard to weld steels

Typical Base Material Grades

High-strength unalloyed and heat-treatable steels, ferritic Cr and austenitic CrNi steels, austenitic Mn steels

Unalloyed tempered steels, tool steels, hard manganese steels, hard-to-weld steels

| Standards |

Current Type |

EN ISO 3581-A - E 23 12 L R 32

|

D.C. (+) / A.C.

|

AWS A5.4 - E 309L-17

|

|

| Chemical Composition of Weld Metal % (Typical) |

| C |

Si |

Mn |

Ni |

Cr |

| 0.03 |

0.8 |

0.8 |

12.6

|

23.0 |

| Mechanical Properties |

Yield Strength

(N/mm2) |

Tensile Strength

(N/mm2) |

Impact Strength

(ISO-V/+20ºC)

|

Elongation

(Lo=5do)(%) |

min. 440

|

540 - 720

|

min. 47 J |

min. 30

|

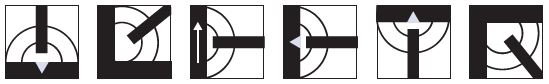

Welding Positions

| Operating Data |

| Diameter x Length (mm) |

Welding Current (A) |

Package

Weight (Kg) |

No. Pieces Approx |

|

2.50 x 250

3.20 x 350

|

60 - 90

80 - 120

|

0.5

0.5

|

TBC

TBC

|

Liability: Whilst all reasonable efforts have been made to ensure the accuracy of the information contained. This information is subject to change without notice and can be only considered as suitable for general guidance.